Reliability is the proportion of time a system delivers its intended functionality without a failure. Reliability can be expressed as uptime and calculated from Mean Time Between Failure (MTBF) or the invers of it, failure rate (λ).

Maintainability is a measurement of time to repair the asset, it is the downtime and can be expressed quantitatively as:

VAES pioneered a range of software which are automating laborious and time-consuming processes into digital reasoning models. That has effectively helped our clients to fast track processes and reaching desirable results in a feasible manner.

How can we help:

- Mean Active Repair Time (MART): Includes Fault diagnosis, removing covers and dismantling, repair of asset, and restarting the asset back into service

- Mean Time To Repair (MTTR): Includes Mean Incident Detection Time (MIDT), Mean Incident Response Time (MIRT) is composed of logistic preparation time and MART. Hence the relation:

MTTR = MIDT + MIRT + MART

Availability: The proportion of time a system is delivering its intended functionality. It can be mathematically expressed as:

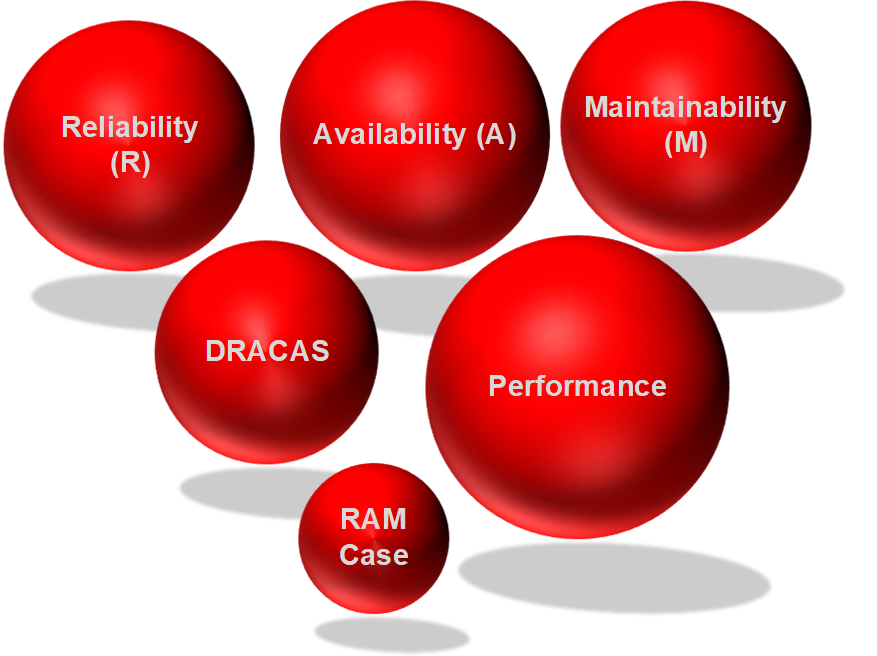

In the RAM world, VASE can deliver the following:

1- Deriving and Apportioning RAM Model

Starting from the intended performance of existing or under development assets, we prepare and simulate RAM model with its main parameters: uptime, downtime and availability.

For the large-scale projects, we have the skillsets and expertise to apportion those parameters and instruct them as RAM targets to several contractors

With carefully drawn plan and strategy, we enable the principle contractor to control the progress, interface and integration of those portions and eventually demonstrate the delivery of the intended performance.

2- RAM in the Design Development Process

Knowing and bearing in mind RAM targets throughout systems design, installation and integration stages, are essential to identify and eliminate critical performance issues and supporting the resilience of the final product.

This would effectively de-risk major changes at advanced lifecycle stages, which usually come with a very high cost or a failure of the delivery of the asset.

3- Writing RAM Case

The development of a RAM case is regulated over most of the industries. Our team can comply with the respective regulations and deliver an approvable RAM case.

As the design grows, we develop RAM assumptions and claims, which will then be consolidated, validated and demonstrated.

In another important role, consolidated and validated assumptions are indeed technical specifications which must be considered and influence the procurement process.

Claims are to be validated during T&C. Fail-to-meet claims would be realised by DRACAS/FRACAS and covered by a reliability growth plan.

4- DRACAS/FRACAS

Failure/Data Recording and Corrective Action System (DRACAS/FRACAS) is a tool to formally record and classify data about defects and corrective actions that occur during testing phases and operational life of the mechanical, electrical and public health systems.

DRACAS/FRACAS data enabling a traceable and auditable trail for any subsequent investigation into the design and manufacture of assets.

DRACAS/FRACAS is among our web-based application with a centralised database. Our service in this regard demonstrated success in delivering effective reliability growth program for very big scales projects.